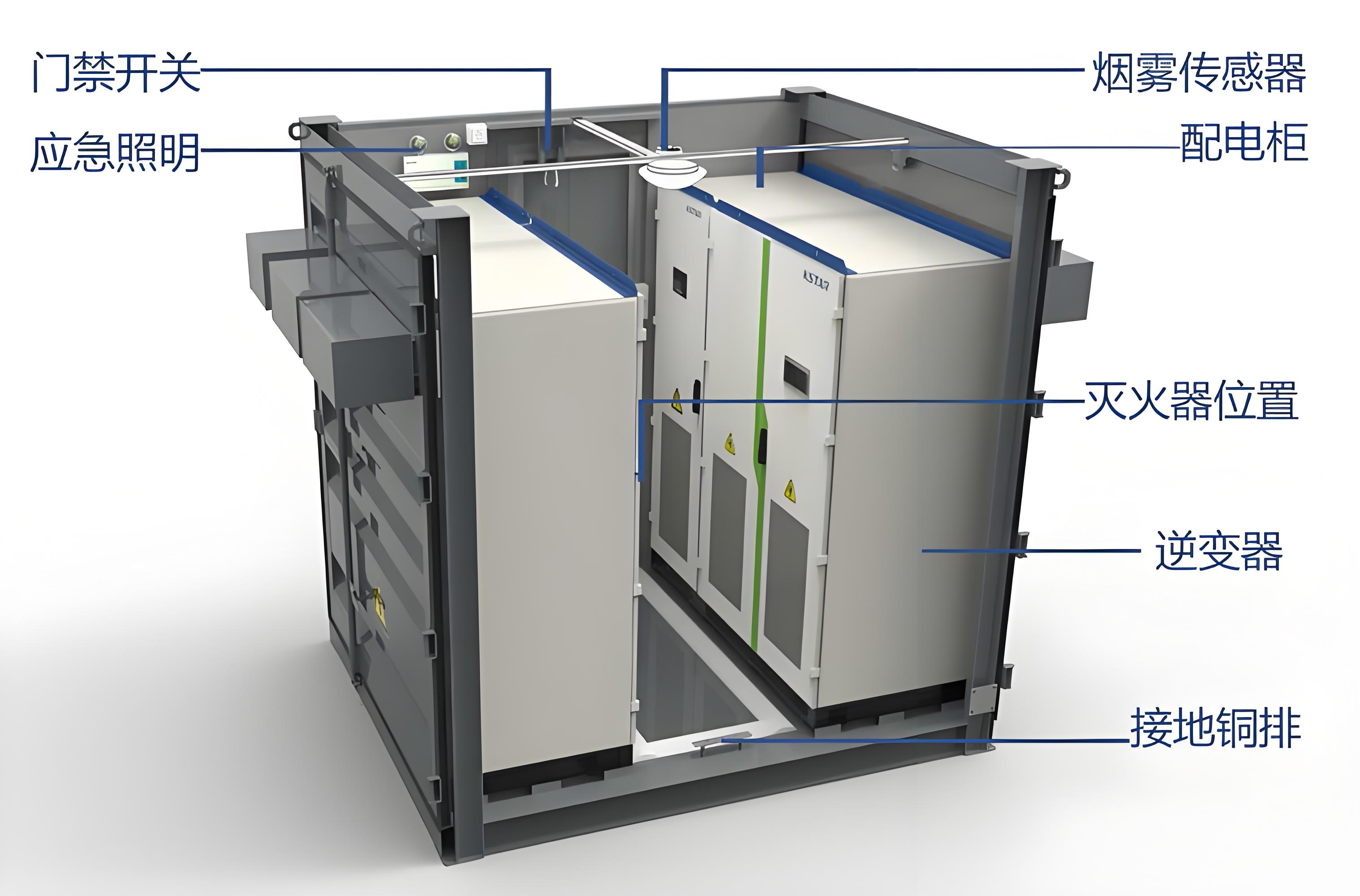

Design scheme The design of inverter containers needs to consider a number of factors, including heat dissipation, protection and integrated function design. 1. Thermal design : The use of segmented straight air duct, air duct does not contain fan, zero loss, maintenance-free. The length of the air duct is only 1 meter, the pressure loss is small, and the fan is in the best efficiency state. When the inverter is working, most of the heat is discharged out of the container through the air duct, and some of the heat is radiated into the box to ensure the long-term reliable operation of the inverter . 2. Protective design : The container inverter room combines the functions of heat dissipation and protection with the inverter products, and has good dustproof, waterproof and anti-corrosion capabilities. By adding shutters on the side of the container, the external cold air directly enters the container through the side window and continuously flows on the back of the inverter, improving the heat dissipation efficiency . The installation and operation of the inverter container is relatively simple, and the main advantages include: 1. Short construction period : container scheme by hoisting directly placed in the designated place, without complex construction process, greatly reducing the difficulty of construction and site risk . 2 high cost-effectiveness : compared with the traditional inverter scheme in cement house, the container scheme has significant advantages in construction time and project cost, especially in the areas with high labor cost and difficult construction . 3. Easy maintenance : container-type inverter room integrates inverter and DC cabinet into one, easy maintenance, concise air duct design, reduces maintenance costs . |